Superomniphobic Surfaces

Superomniphobic surfaces are extremely repellent to virtually any liquids. Due to their unique functionality, superomniphobic surfaces have a wide range of applications including (but not limited to) self-cleaning, anti-fouling, drag reduction, corrosion prevention, and chemical shielding. Superomniphobic surfaces are typically developed by combining re-entrant textured surfaces with low surface energy that can support the contacting liquid in the Cassie-Baxter state.

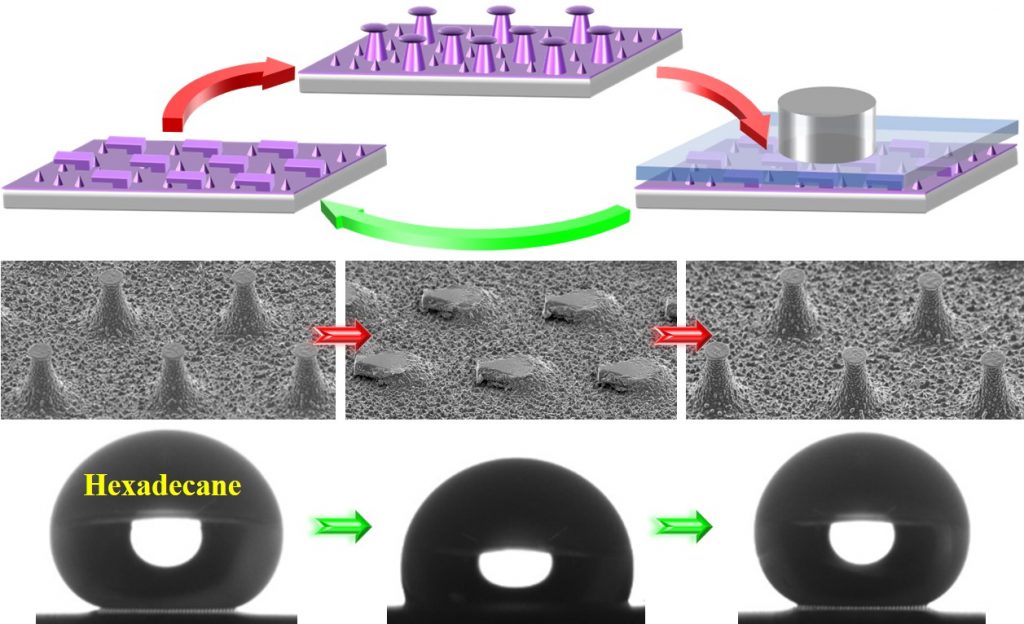

In our work (Wang et al., Adv. Mater., 2017), we designed the metamorphic superomniphobic (MorphS) surfaces that transform their morphology in response to heat by combining superomniphobicity and shape memory effect. Utilizing our MorphS surfaces, we demonstrated the distinctly different wetting transition of liquids with different surface tensions and elucidate the underlying physics.

We envision that our robust MorphS surfaces with reversible wetting transition will have a wide range of applications including rewritable liquid patterns, controlled drug release systems, lab-on-a-chip devices, and biosensors.

Our current efforts are focused on developing multifunctional superomniphobic surfaces.

Omniphobic Membranes

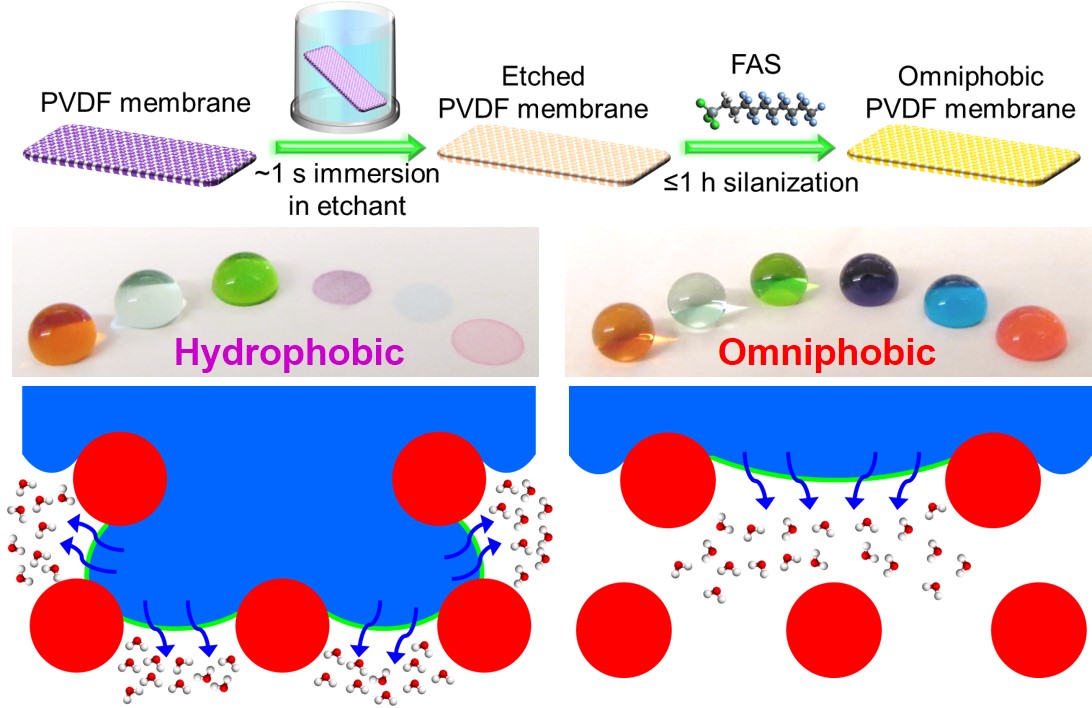

Membrane distillation (MD) is an emerging desalination technology for water purification. Maintaining membrane wetting resistance is critical in MD. Conventional hydrophobic MD membranes suffer from membrane wetting in desalination of feedwater containing low surface energy contaminants. Very recently, it has been demonstrated that membrane wetting induced by low surface energy contaminants can be significantly mitigated in MD by imparting omniphobicity to the membranes.

In our work (Wang et al., Nat. Commun., 2019), we developed novel monolithic omniphobic MD membranes, which display excellent wetting resistance against liquids with low surface tensions. Further, we discovered a trade-off between wetting resistance and water vapor permeability in MD process. Utilizing membranes with tunable wetting resistance and permeability, we elucidate the underlying mechanism of such trade-off.

We envision that the wetting resistance-permeability trade-off as well as the mechanistic insight conveyed in our work will pave the way for smarter design strategies for high-performance MD membranes, thereby promoting the cost- and energy-efficiencies of MD desalination for water purification.

Our current efforts are focused on developing membranes with both high wetting resistance and water vapor permeability.

Deicing Coatings

Adhesion and build-up of ice on exposed surfaces (e.g., airplanes, ships, power lines, offshore oil drilling platforms) is a severe hazard that affects many aspects of our daily life. Deicing coatings with low ice adhesion strength (i.e., the critical shear stress required to separate ice from a material) can facilitate easy removal of ice.

In our work (Beemer et al., J. Mater. Chem. A, 2016), building on the principles of adhesion mechanics, we developed novel inexpensive, environmentally benign, non-corrosive PDMS gels that offer ultra-low adhesion to ice as well as outstanding mechanical durability. We elucidated the mechanism of separation of ice from our PDMS gels via separation pulses.

We envision that our durable PDMS gels with ultra-low ice adhesion strength as well as the improved understanding of the separation mechanism will enable universal deicing design strategies in aviation, maritime, power, automotive, and energy sectors.

Our current efforts are focused on developing icephobic coatings that possess both anti-icing and de-icing functions.